Which of these statements regarding cockpit windows are correct or incorrect .i ? [ Assessment Aerodrome ]

Question 19-1 : I is correct ii is incorrect i is correct ii is correct i is incorrect ii is incorrect i is incorrect ii is correct

I is correct, ii is incorrect.

I is correct, ii is incorrect. Which of these statements concerning a sandwich structural part are correct or ?

Question 19-2 : I is incorrect ii is incorrect i is correct ii is correct i is incorrect ii is correct i is correct ii is incorrect

I is incorrect, ii is incorrect.

I is incorrect, ii is incorrect. Which of these statements regarding cockpit windows are correct or incorrect .i ?

Question 19-3 : I is incorrect ii is correct i is correct ii is correct i is incorrect ii is incorrect i is correct ii is incorrect

I is incorrect, ii is correct.

I is incorrect, ii is correct. Which of these statements about sandwich structural parts are correct or ?

Question 19-4 : I is incorrect ii is incorrect i is correct ii is correct i is incorrect ii is correct i is correct ii is incorrect

I is incorrect, ii is incorrect.

I is incorrect, ii is incorrect. Which of these statements regarding cockpit windows are correct or incorrect .i ?

Question 19-5 : I is incorrect ii is incorrect i is correct ii is correct i is correct ii is incorrect i is incorrect ii is correct

I is incorrect, ii is incorrect.

I is incorrect, ii is incorrect. Which of these statements regarding cockpit windows are correct or incorrect .i ?

Question 19-6 : I is correct ii is correct i is incorrect ii is correct i is incorrect ii is incorrect i is correct ii is incorrect

I is correct, ii is correct.

I is correct, ii is correct. Which of these statements about composite and metal structures are correct or ?

Question 19-7 : I is correct ii is correct i is correct ii is incorrect i is incorrect ii is correct i is incorrect ii is incorrect

I is correct, ii is correct.

I is correct, ii is correct. Which of these statements about composite and metal structures are correct or ?

Question 19-8 : I is incorrect ii is incorrect i is correct ii is correct i is correct ii is incorrect i is incorrect ii is correct

I is incorrect, ii is incorrect.

I is incorrect, ii is incorrect. Which of these statements about composite and metal structures are correct or ?

Question 19-9 : I is correct ii is incorrect i is incorrect ii is correct i is correct ii is correct i is incorrect ii is incorrect

I is correct, ii is incorrect.

I is correct, ii is incorrect. What are the three elements of the fuselage structure of a large transport ?

Question 19-10 : Skin frames stringers skin ribs formers skin spars ribs skin girders webs

Skin, frames, stringers.

Skin, frames, stringers. Which of these statements about composite and metal structures are correct or ?

Question 19-11 : I is incorrect ii is correct i is correct ii is correct i is correct ii is incorrect i is incorrect ii is incorrect

I is incorrect, ii is correct.

I is incorrect, ii is correct. A sandwich type structure is often used in aircraft because of its ?

Question 19-12 : Low mass and high stiffness low mass and low stiffness ease of deformation under load high temperature resistance

Low mass and high stiffness.

Low mass and high stiffness. A wing spar typically consists of ?

Question 19-13 : A web and girders ribs and stiffeners frames and webs ribs and frames

A web and girders.

A web and girders. A semi monocoque aircraft fuselage structure usually consists of ?

Question 19-14 : Skin frames stringers ribs front spar rear spar ribs spars skin frames fittings stringers

Skin, frames ,stringers.

Skin, frames ,stringers. A sandwich structural part is unsuitable for absorbing ?

Question 19-15 : Concentrated loads bending loads torsional loads shear loads

Concentrated loads.

Concentrated loads. Which of these statements concerning a sandwich structural part are correct or ?

Question 19-16 : I is incorrect ii is correct i is correct ii is correct i is incorrect ii is incorrect i is correct ii is incorrect

I is incorrect, ii is correct.

I is incorrect, ii is correct. Which of these statements about sandwich structural parts are correct or ?

Question 19-17 : I is correct ii is incorrect i is incorrect ii is incorrect i is incorrect ii is correct i is correct ii is correct

I is correct, ii is incorrect.

I is correct, ii is incorrect. Which of these statements about sandwich structural parts are correct or ?

Question 19-18 : I is incorrect ii is correct i is incorrect ii is incorrect i is correct ii is correct i is correct ii is incorrect

I is incorrect, ii is correct.

I is incorrect, ii is correct. The function of ribs in a wing is to ?

Question 19-19 : Give the wing the desired aerodynamic shape withstand the torsional loads withstand all the structural loads allow installation of fuel cells in the wing

Give the wing the desired aerodynamic shape.

Give the wing the desired aerodynamic shape. The pressurisation load on the skin of a fuselage is ?

Question 19-20 : Tension torsion bending compression

Tension.

Tension. When the wing skin is not able to carry loads the structural elements of the ?

Question 19-21 : The spars the ribs the webs the rivets

The spars.

The spars. Which of these statements about the wing structure is correct ?

Question 19-22 : A torsion box is formed by wing spars ribs and wing skin reinforced by stringers a wing main spar consists of a web with stringers a semi monocoque structure consists of the skin and frames the slats are a part of the torsion box

A torsion box is formed by wing spars, ribs and wing skin reinforced by stringers.

A torsion box is formed by wing spars, ribs and wing skin reinforced by stringers. The purpose of bonding the metallic parts of an aircraft is to .1 prevent ?

Question 19-23 : 2 4 1 4 2 3 1 3

2, 4.

2, 4. Which sequence correctly places the fuselage shapes illustrated in order of ?

Question 19-24 : 2 3 4 1 1 3 4 2 1 4 3 2 3 1 2 4

2, 3, 4, 1.

2, 3, 4, 1. Hydraulic fluids must have the following characteristics .1 thermal ?

Question 19-25 : 1 2 3 and 4 1 2 5 and 7 2 3 4 and 5 1 3 4 and 6

1, 2, 3 and 4.

1, 2, 3 and 4. Hydraulic fluids ?

Question 19-26 : Are irritating to e and skin are irritating to e and skin and cause high fire risk cause high fire risk do not require special care

Are irritating to eyes and skin.

Are irritating to eyes and skin. Hydraulic fluids used in systems of large modern airliners are ?

Question 19-27 : Phosphate ester base fluids water base fluids vegetable base fluids mineral base fluids

Phosphate ester base fluids.

Phosphate ester base fluids. Hydraulic power is a function of ?

Question 19-28 : System pressure and volume flow pump rpm only system pressure and tank capacity pump size and volume flow

System pressure and volume flow.

System pressure and volume flow. Large transport aeroplane hydraulic systems usually operate with a system ?

Question 19-29 : 3000 psi 4000 psi 2000 psi 1000 psi

3000 psi.

3000 psi. In hydraulic systems of large modern transport category aircraft the fluids ?

Question 19-30 : Synthetic oil mineral oil water and glycol vegetable oil

Synthetic oil.

Synthetic oil. The type of hydraulic oil used in modern hydraulic systems is ?

Question 19-31 : Synthetic oil vegetable oil mixture of mineral oil and alcohol mineral oil

Synthetic oil

Synthetic oil In a modern hydraulic system 'hydraulic fuses' can be found their function is ?

Question 19-32 : To prevent total system loss in case of a leaking hydraulic line to switch to the secondary system in case of a leak in the primary brake system to isolate a part of the system and protect it against accidental pollution to allow by passing of a hydraulic pump in case it is subject to excessive pressure without further damage to the system

In a hydraulic system the reservoir is pressurized in order to ?

Question 19-33 : Prevent pump cavitation reduce fluid combustibility seal the system keep the hydraulic fluid at optimum temperature

Prevent pump cavitation.

Prevent pump cavitation. Shuttle valves will automatically ?

Question 19-34 : Switch hydraulically operated units to the most appropriate pressure supply guard systems against overpressure reduce pump loads shut down systems which are overloaded

Switch hydraulically operated units to the most appropriate pressure supply.

Switch hydraulically operated units to the most appropriate pressure supply. The colour of a fresh synthetic hydraulic fluids is ?

Question 19-35 : Purple pink blue red

Purple.

Purple. The function of a hydraulic selector valve is to ?

Question 19-36 : Direct system pressure to either side of the piston of an actuator select the system to which the hydraulic pump should supply pressure automatically activate the hydraulic system discharge some hydraulic fluid if the system pressure is too high

Direct system pressure to either side of the piston of an actuator.

Direct system pressure to either side of the piston of an actuator. The component that converts hydraulic pressure into linear motion is called ?

Question 19-37 : An actuator or jack a hydraulic pump a pressure regulator an accumulator

An actuator or jack.

An actuator or jack. The hydraulic device which functionality is comparable to an electronic diode ?

Question 19-38 : Check valve flow control valve distribution valve shutoff valve

Check valve.

Check valve. Hydraulic fluid entering the hydraulic pump is slightly pressurised to ?

Question 19-39 : Prevent cavitation in the pump prevent overheating of the pump prevent vapour locking ensure sufficient pump output

Prevent cavitation in the pump.

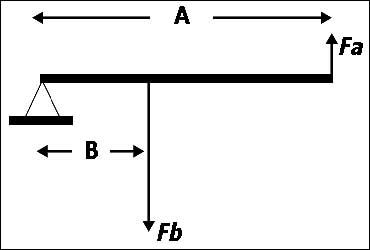

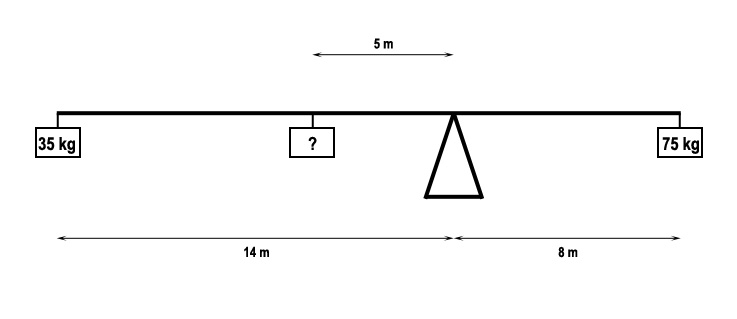

Prevent cavitation in the pump. In the hydraulic press schematically shown what balancing force would be acting ?

Question 19-40 : 100 n 1000 n 20 n 1 n

100 n.

100 n. ~

Exclusive rights reserved. Reproduction prohibited under penalty of prosecution.

719 Free Training Exam Other source study: Ppl exam examen 19